The tooling that you select to support your CadCam workflow should be considered carefully. Tools weigh heavily on the quality and efficiency of your production process. It’s surprising that many labs don’t consider their tooling options thoroughly. In this post, we’re going to cover some of the things that you should be thinking about when looking at a tooling solution.

Tools Directly Affect Profitability.

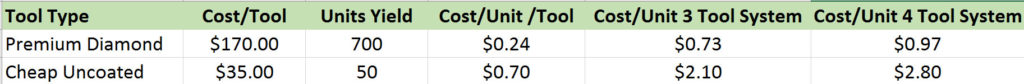

The cost of tooling accounts for a big part of your cost to produce a zirconia restoration. It’s definitely worth looking at. When it comes to picking tools for your lab you have a couple of options: One is to choose inexpensive tools and save money on the purchase of the tools. Alternatively, you can spend more upfront on the tools and save money on your overall process.

The best way to quantify this is to look at your tooling cost per unit produced. Take a few minutes and calculate your milling tool cost per unit. The way you do it may vary, but usually we tell labs to figure it on a monthly basis. Take your monthly spend on tooling and divide it by your monthly unit production.

Now that you know where you sit, take a look at the example below and compare:

As you can see, the performance of your milling tools has a direct effect on your labs bottom line. It’s surprising to see how much can be saved per unit by spending more upfront on your tooling. If you’re still using lower yield tools it might be time to reconsider.

Better Tools Reduce Indirect Costs.

Not only do good tools help your per unit cost drastically, they also reduce other costs around the lab.

- One of the biggest ones is the reduction of internal remakes. When you factor in material, labor, and opportunity cost, the actual expense of a remake is incredibly high. If you can avoid a remake you should. Using long-lasting tools help you avoid machine related remakes because they will run many more units before chipping and other adverse results start to appear.

- Good tooling reduces labor cost. There are labor savings in the reduction of remakes, repairs on milling related defects, and also less time spent changing tools out.

- Premium tools are easier to your equipment. High-quality coatings and optimum cutting geometry reduce the cutting force during milling. Lower cutting forces reduce the wear and tear on your milling machine which helps you get more from your investment.

The Takeaway:

It’s always important to look at the big picture. It can be a mistake is to focus on the micro when you should be focusing on the macro. If you consider how each buying decision affects your overall system you always come out ahead.