What is a “Stepper Motor”?

[ˈstepər] [ˈmōdər]

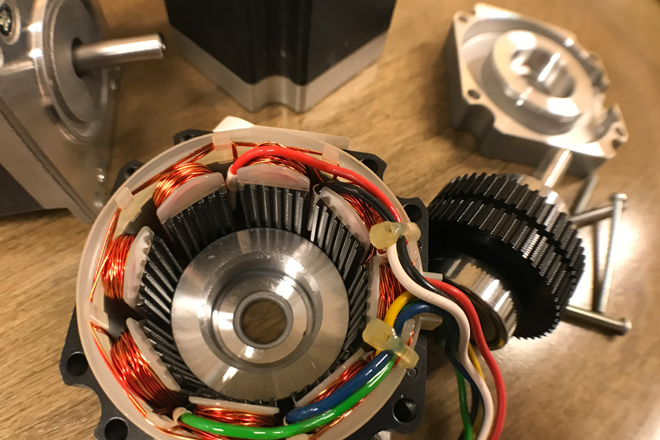

A stepper motor is a special type of electric motor that is used in our dental CNC machines. These motors control the position of each of the machine’s axes. Stepper motors are different from regular electric motors because they offer extremely precise position control. Regular motors, while much more commonplace are only controllable in terms of rotational speed. On the other hand, stepper motors use a toothed rotor design in combination with a microcontroller to directly control the rotational position of the motor. This arrangement allows a computer to send a signal to the motor and tell it to move to or hold at any rotational position – with micron level accuracy. This exact control is then combined with high precision mechanisms to create the CNC machine’s axis. Stepper motors are a key component in all the CNC machines dental labs use today.

Interesting Details about “Stepper Motor”:

- How do they work? Stepper motors use toothed electromagnets to divide their rotation into equally distributed “steps”. They are controlled by an external circuit that produces pulse signals. The signals correspond to the relative position of the electromagnet and the motor’s rotor/shaft. This allows unique pulse signals to move the motor’s shaft to a fixed angle, thus providing the positional control needed.

- They don’t require a feedback loop. One of the largest benefits of stepper motors over other means of mechanical control is that they do not need an external feedback loop to know where the motor is positioned. Stepper motors “know” where they are based on the input signal. This is especially useful in keeping the cost of our machines low because it simplifies the setup substantially.

- There’s a huge variety available. Stepper motors are produced to meet nearly any industrial need. They are classified by the size of the frame and mounting bracket. The sizing standard is set by NEMA. This standard controls the basic size and shape of the motor, but not any of its other technical specifications. Motors are selected for their specific application and are not necessarily interchangeable based on size. The desktop dental machines that are common today typically use NEMA 17 or NEMA 23 sized motors.

- They’re relatively inexpensive. They’re simple, and cheap to produce. Naturally, there is a variance in the quality from different manufacturers – so the price does range. However, cheap versions of the motors commonly used in our machines can be found online for less than $10 each.

- Other applications in the lab? Anywhere there is a need for computer mechanical control, you’re likely to find a stepper motor. Around the dental lab, they are used in any CADCAM equipment that has moving parts. This includes all lab scanners and 3d printers.

Thanks for reading! We hope this break down of the term “Stepper Motor” has been of value. Stay tuned next week for another post like this!

Check out the growing list of WeTeamUp Terms posts HERE